If you have uneven concrete slabs on your property, there’s a good chance that concrete jacking is the perfect solution for you. If you are unfamiliar with this service, however, you’re likely unaware of how valuable it can be. Read on to learn all that and more!

What’s the Purpose of Concrete Jacking?

The primary purpose of concrete jacking (also known as “slab jacking”) is to level concrete slabs that have become sunken and uneven over the years. Typically, slabs become unlevel because the soil beneath them has shifted enough to form gaps of empty space.

As the slabs sink into those empty spaces, their surfaces become unlevel, difficult to use, and dangerous. Given the tripping hazard that unlevel concrete can cause, finding a quick fix is a must. Fortunately, concrete jacking is a quick and simple way to restore your concrete to its original state.

What’s the Process for Leveling Concrete Slabs?

Now that you understand the basic purpose, it’s time to learn how the process of concrete jacking unfolds. The sections below will detail the main steps a concrete professional will take when providing this service to you.

Identify the Sunken Areas

The first step in any slab jacking job is to do a careful evaluation of the slabs you plan to level. By taking time to identify the precise locations in which the slabs have the most sunken concrete, professionals can develop a strategic approach to the rest of the concrete jacking process.

Drill Holes through the Slab

After identifying the areas of the slabs that need a lift, the next step is to drill holes through the top of the slab. Carefully drilling these holes in the specific locations identified in step one gives your concrete team the access they need to the empty soil gaps causing your uneven concrete.

Inject the Slab Jacking Material

Once the holes are in place, the main stage of the concrete jacking process will happen. At this point, it is time to inject a jacking material into the holes. This material will enter the holes and fill the gaps below. Once the gaps are full, injecting additional material brings your slabs to the ideal level for safe, functional use.

Clean and Seal the Holes

After bringing your slab to the correct level, it is time to clean the injection holes and help them blend in with the rest of the slab. The most common way to achieve this is to apply a small amount of concrete to cover the hole and make it look almost like it isn’t there.

Let Everything Dry

The final step is to wait for the concrete jacking material and the concrete patchwork on the injection holes to dry. Once both have dried, you will be ready to walk on your newly-restored concrete slab.

Types of Concrete Jacking

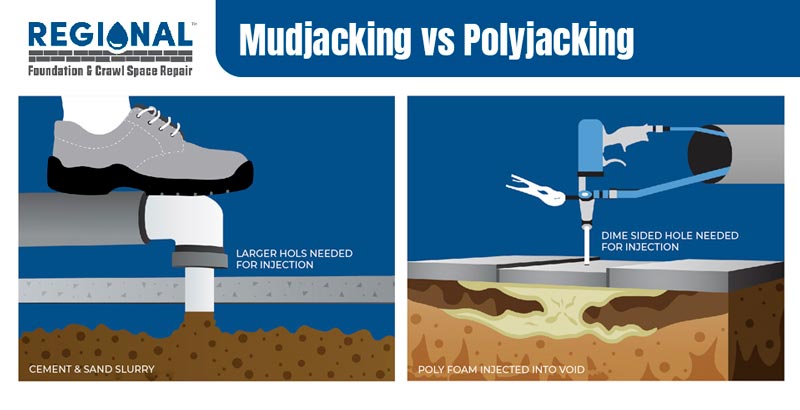

There are two main types of slab jacking you should know about before seeking this repair service for your property. Both mudjacking and polyjacking are quite similar. In fact, the only key difference between mudjacking and polyjacking is the material that gets injected below your slabs. Although mudjacking and polyjacking are very similar in many ways, each material has distinct advantages and disadvantages, as the sections below will show.

Mudjacking

Mudjacking involves injecting a cement slurry mixture beneath your concrete slabs. This mixture takes about 1-2 days to fully cure, and requires an injection hole that is about 2 inches in diameter.

Between the two options, mudjacking material proves to be the least expensive. However, there are several ways in which polyjacking reveals itself as the more effective material option.

Polyjacking

In contrast to the slurry used in mudjacking, the polyjacking process relies on polyurethane foam. This foam material comes with several clear advantages that make polyjacking the better option despite its higher upfront cost.

First, polyjacking typically requires a smaller injection hole that measures less than an inch in diameter. This smaller hole will be easier to conceal and blend with the rest of the concrete when the job is done.

Polyjacking foam also has a much faster drying time. Amazingly, this material can be ready to walk on just 15 minutes after the repair is complete. Additionally, this hardened foam tends to be more resistant to moisture, boosting its longevity. So, while it may cost more, the almost immediate results–combined with excellent longevity–make polyjacking the better option in most cases.

Get a Professional to Level Your Concrete

If you are dealing with uneven concrete, you should understand the advantages concrete jacking can offer you. This service is typically convenient and effective for leveling your concrete, and proves to be far more cost-effective than replacing your slabs entirely.

When you decide that concrete jacking is right for you, your next step is to find a team that can provide that service for you. If you live in Eastern North Carolina, Regional Foundation & Crawl Space Repair is that team.

While we have extensive experience repairing and enhancing foundations and crawl spaces, we are also experts at slab jacking. For all of our slab jacking jobs, we use a top-of-the-line polyjacking material known as PolyLevel. If you want to learn more about how we can use PolyLevel to fix your unlevel concrete, reach out for a free estimate today!