Services

Get Your Free Estimate Now!

Serving the Triad, Triangle and Eastern North Carolina

to the Coast.

Are you tired of looking at sunken, uneven concrete? From sidewalks and driveways to patios, pool decks, and interior slabs, our team has the expertise to bring your concrete back to its pristine condition.

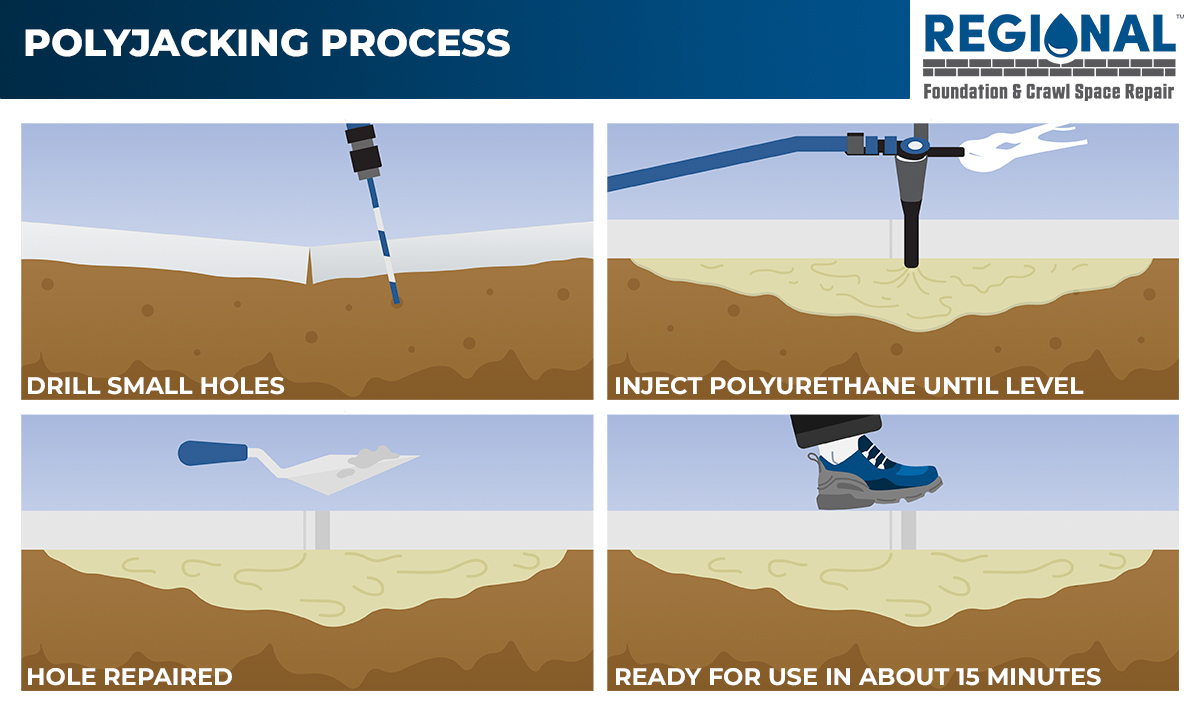

Concrete leveling using PolyLevel® is a popular method used to repair uneven and sunken concrete surfaces. PolyLevel® is a process that involves injecting a polyurethane foam mixture into the soil beneath the concrete surface. This foam mixture expands and hardens, raising the concrete to its original level. This technique is highly effective, cost-efficient, and less disruptive to the surrounding environment than traditional methods.

Step 1: Site Inspection and Preparation

The first step involved in the PolyLevel® process is a site inspection. An experienced technician will assess the site and determine the extent of the damage. The technician will then prepare the site, which includes removing any debris or obstacles that may interfere with the process.

Step 2: Drilling

Once the site has been prepared, the technician will drill small, dime-sized holes in the affected area of the concrete. These holes are drilled strategically to allow for the injection of the polyurethane foam mixture.

Step 3: Injection of Polyurethane Foam

After drilling holes, the technician will inject the polyurethane foam mixture into the soil beneath the concrete surface. The injection is done using specialized equipment that pumps the foam mixture through the holes and into the soil. As the foam mixture enters the soil, it expands, filling any voids and crevices.

Step 4: Monitoring and Leveling

Once the foam mixture has been injected, the technician will monitor the progress of the leveling process. The foam mixture will continue to expand until it reaches its maximum level, at which point the technician will stop the injection process. The technician will then assess the level of the concrete and make any necessary adjustments.

Step 5: Clean-Up

After the PolyLevel® process is complete, the technician will clean up the site. This involves removing any excess foam and filling the holes with a compound that closely matches the color of the concrete. The site will be left clean and neat, ready for use.

One of the most significant advantages of the PolyLevel® system is that it is lightweight. The high-density polyurethane foam used in this system weighs only about two pounds per cubic foot, making it an excellent option for lifting and leveling large concrete surfaces like sidewalks and driveways. This foam is considerably lighter than the concrete it raises, which means that it puts less pressure on the soil beneath the concrete. This, in turn, reduces the risk of soil settling and further sinking of the concrete.

The PolyLevel® system boasts an impressive lifting capacity and can handle substantial loads. It is engineered to withstand extreme weather conditions, freeze-thaw cycles, and heavy traffic, making it an ideal solution for commercial, industrial, and residential applications.

When it comes to concrete leveling, precision is critical. And that’s where the PolyLevel® system shines. With its advanced technology and superior material, our system can achieve highly accurate lifts that perfectly level your concrete surface.

The secret to our precision lies in our expert technicians’ careful control of the reaction time. By monitoring and adjusting the chemical reaction that lifts the concrete, our technicians can achieve the exact level needed. This level of control is especially crucial for critical applications, such as matching an existing surface.

The PolyLevel® system is also incredibly durable. The polyurethane foam is water-resistant and won’t erode or wash away over time. Plus, it won’t shrink or settle like traditional mudjacking solutions, which can eventually lead to the same problems you were trying to fix in the first place.

Another significant benefit of the PolyLevel® system is that it is quick and easy, minimizing disruptions to your daily routine. Our certified technicians can swiftly and efficiently complete the concrete lifting process, ensuring that your surface is level and ready for use in no time. Further, the PolyLevel® system is cost-effective, saving you money in the long run by preventing further damage to your concrete surface and avoiding costly repair or replacement.

Another advantage of the PolyLevel® system is its quick cure time. The material is set within 15 minutes of application, which means you can walk or drive on the surface immediately after the work is completed. This reduces downtime and disruption to your daily routine, making it an ideal solution for busy areas such as sidewalks and driveways.

The PolyLevel® system can be used to recycle existing materials. For example, it can lift and repair old concrete slabs, reducing the need for new materials and minimizing waste. This approach makes the PolyLevel® system an excellent choice for those looking for sustainable and eco-friendly solutions.

At our company, our approach to concrete repair is comprehensive, involving careful assessment, detailed planning, expert application, and successful results.

Hear from our satisfied customers who attest to the quality and durability of our concrete repair services:

In most cases, depending on the size and complexity of the project, concrete leveling using PolyLevel® can be completed in just a few hours. This is a stark contrast to traditional methods of concrete leveling, like mudjacking, which can take days or weeks to complete.

The good news is that once the foam is fully cured, it is safe around your loved ones and the environment. Polyurethane foam is well known for its excellent environmental credentials and is often used in green building projects. It is non-toxic, hypoallergenic, and emits no harmful chemicals or fumes.

When it comes to landscaping, PolyLevel® is one of the least invasive repair methods available. Unlike traditional concrete repair methods, such as excavation and replacement, PolyLevel® does not require heavy machinery or large amounts of material to be removed from the site. This means that your garden or lawn will not be disturbed, and landscaping features such as flower beds, tree roots, or water features will not be affected.

If the slab has suffered significant structural damage, it may not be possible to use PolyLevel®. In such cases, replacement may be the only viable option. This involves removing the damaged slab and pouring a new one in its place. While this is a more involved and expensive process than PolyLevel®, it is necessary to ensure the safety and integrity of the structure in question.

For more information, see:

How to Identify and Fix Common Concrete Repair Issues

The Complete Guide to Concrete Crack Repair: Methods and Tips

Understanding Spalling Concrete: Causes and Repair Solutions

Contact Regional Foundation and Crawl Space Repair today to schedule an assessment of your concrete repair needs. Our experienced team is ready to offer a quick, efficient, and eco-friendly solution to restore your surfaces to perfection.

Get Your Free Estimate Now!

Serving the Triad, Triangle and Eastern North Carolina to the Coast.