Understanding Concrete Flatwork: Basics and Installation

Introduction to Concrete Flatwork

When we think about concrete flatwork, the imagery that often comes to mind involves driveways, foundation slabs, sidewalks, patios, and floors – essentially, any flat, horizontal surface made with concrete. But there’s much more to it than just laying down a slab. The first step in creating a resilient and visually appealing concrete surface starts with understanding its composition and the intricate process involved in its installation, such as pouring, leveling, and finishing concrete to create horizontal surfaces in construction.

Understanding the Basics

The Composition of Concrete

Concrete is a composite material from water, aggregate (sand, gravel, or crushed stone), and cement. When water and cement are mixed, a chemical reaction known as hydration binds the aggregate particles together and hardens the mixture into a solid mass.

Too much water can weaken the concrete by causing the cement particles to spread out and leave voids in the mix. On the other hand, too little water can make the concrete challenging to work with during placement and finishing, leading to a rough and uneven surface. So, to achieve a perfect balance of strength and workability, it is crucial to use the right amount of water in proportion to the amount of cement used.

The hydration process usually takes several weeks to complete, depending on the composition of the cement and surrounding environmental conditions. So, it is essential to maintain proper moisture levels and temperature during the early stages of the process to ensure that the concrete develops the desired strength and characteristics.

Importance of Mix Design in Concrete Flatwork

The quality of concrete flatwork depends particularly on its mix design. This complex process involves carefully selecting the right combination of materials and their proportions to achieve the desired characteristics. The mix design determines the workability, compressive strength, durability, and ability to withstand environmental factors such as freeze-thaw cycles and chemical exposure.

The right mix design can result in flatwork that is easy to place and finish, has high strength and durability, and requires minimal maintenance over its lifespan. On the other hand, a poorly designed mix can lead to cracking, scaling, and other damage that can compromise the functionality and aesthetics of the concrete. So, paying close attention to the mix design is necessary to ensure that the concrete flatwork meets the required standards and performs well over time.

Preparation is Key

Subgrade Preparation

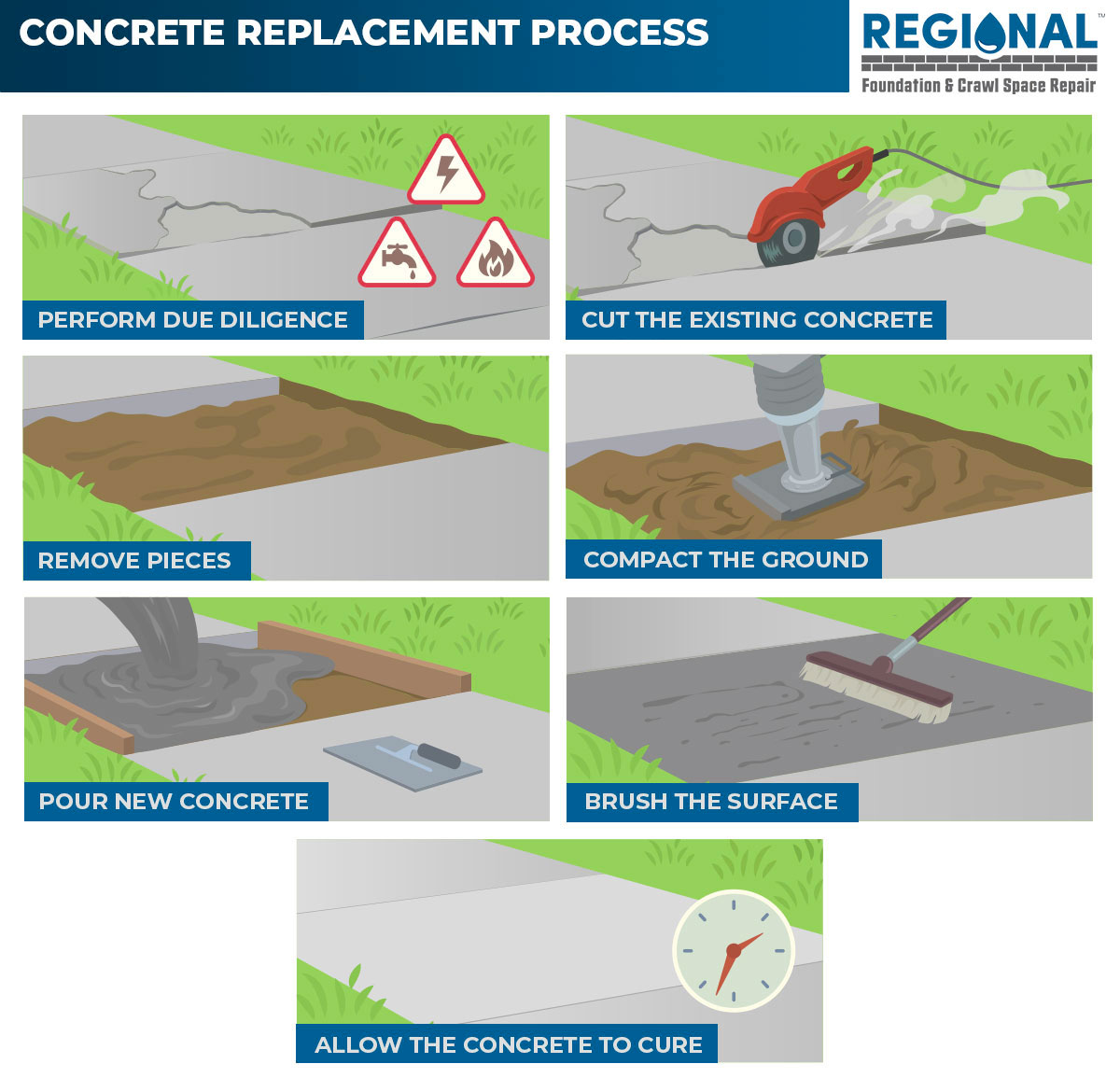

Proper subgrade preparation is a required step in the concrete pouring process. It involves carefully compacting and leveling the soil underneath, forming the concrete’s foundation to prevent problems such as cracking or settling in the future. By preparing the subgrade correctly, you can ensure that your concrete project will be durable, long-lasting, and structurally sound.

Formwork Design

Imagine you’re building a Lego structure, but instead of Legos, you’re using a liquid that turns into rock-hard concrete. You need a mold to ensure this liquid concrete shapes up exactly how you want it—like a smooth driveway or a flat patio. That’s where formwork design comes in. It’s your plan or blueprint for creating a mold that holds the concrete in place.

This mold shapes the concrete into the specific look you want and keeps it supported until it dries and gets strong enough to hold itself up. Getting this mold right is super important because it determines how thick your concrete will be and whether it’ll have the proper slope or angle.

The Art of Pouring Concrete

Mastering Reinforcement Techniques

Reinforcement techniques such as steel bars or wire mesh resist tension forces that may occur due to changes in temperature or weight. These reinforcements can help prevent cracking and other forms of damage to the concrete.

Steel bars are commonly used as reinforcement in a grid pattern throughout the concrete. Wire mesh can be an alternative to steel bars. It is important to note that the reinforcement method will depend on the concrete flatwork and the expected load.

The Finishing Touch

Concrete finishing is where skill truly shines. The process typically involves several steps, including leveling and smoothing the surface, applying textures, patterns, or colors, and sealing the surface to protect it from moisture, stains, and wear and tear. The techniques used in concrete finishing may include troweling, brooming, stamping, and polishing, depending on the desired outcome.

- Troweling involves smoothing the surface with a trowel to create a level and glossy finish.

- Brooming is done by running a broom over the surface to create a non-slip texture.

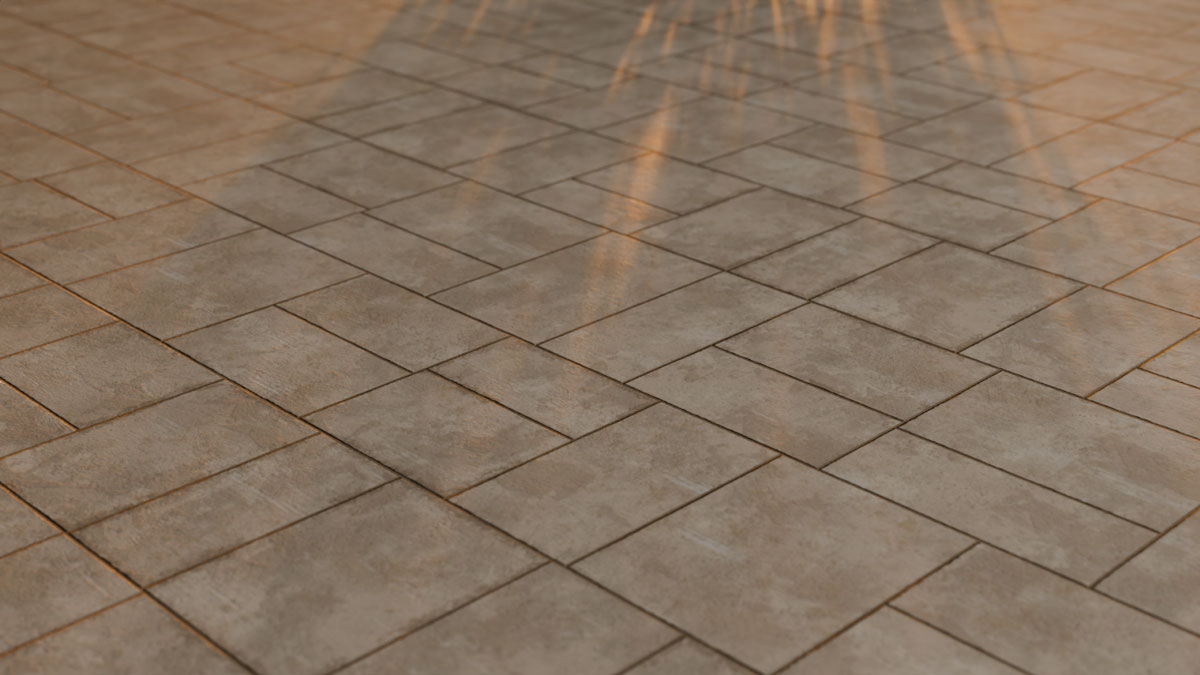

- Stamping is a technique used to create patterns resembling natural stone, brick, or tile, while polishing creates a smooth and shiny finish.

Good concrete finishing requires skill, precision, and attention to detail, as even the slightest mistake can affect the surface’s appearance and performance.

Aftercare: Ensuring Durability

The Curing Process

During the curing process, the concrete is kept moist for a specific time, which allows it to develop its maximum strength potential. This moisture retention process helps to prevent cracking and other damage, which can occur when the concrete dries too quickly. Properly cured concrete flatwork is vital to its durability and longevity, ensuring that the concrete reaches its full strength and can withstand the stresses of everyday use.

Sealing and Maintenance

The final steps of this process include sealing and maintenance. Sealing is a protective measure that safeguards the surface from damage caused by water penetration, stains, and wear. The frequency of resealing your concrete flatwork depends on the type of sealer used, the exposure conditions, and the amount of traffic the surface receives. Experts recommend resealing exterior concrete surfaces every few years to ensure maximum protection.

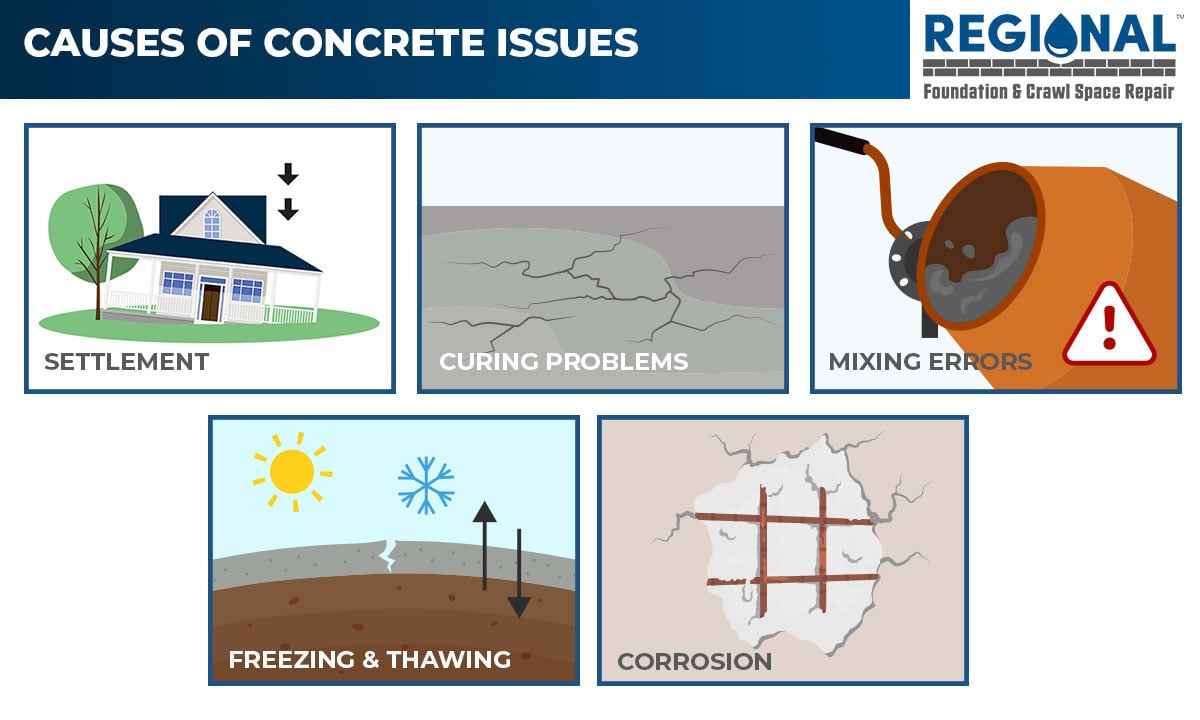

Several factors can cause concrete failure, including freezing and thawing, shrinkage, abrasion, and thermal characteristics. So, taking good care of your concrete flatwork is crucial to prevent these factors from causing damage.

If you notice cracks in your concrete flatwork, don’t panic. Depending on their severity and cause, they can often be repaired. The repair method can range from simple filling and sealing to extensive reconstruction for more significant issues.

We at Regional Foundation & Crawl Space Repair fix cracks using the best-quality epoxy or polyurethane injections to shield the concrete from moisture and add crucial structural support.

Innovations in Concrete Flatwork

Exploring Aesthetic Options

Today, concrete flatwork is about more than just functionality. The aesthetic options are virtually limitless, with various surface textures and coloring techniques.

For instance, surface textures can be added to concrete flatwork to create swirls, cobblestones, and slate patterns. Coloring techniques such as staining, painting, and integral coloring customize the color of the concrete, giving it a unique look that complements the property’s overall aesthetic. Concrete flatwork can now create various designs that transform a dull outdoor space into a stunning visual masterpiece.

Adopting Environmental Considerations

As the world becomes more environmentally conscious, incorporating green practices and sustainability into concrete flatwork projects is necessary. Several environmentally friendly options for concrete flatwork can help reduce the construction industry’s carbon footprint.

One such option is using recycled materials for aggregate in concrete. It not only helps reduce waste but also reduces the need for new mining operations. Another way to reduce the environmental impact of concrete flatwork is to choose lower-carbon cement options. These alternatives have a smaller carbon footprint than traditional cement, produced by heating limestone at high temperatures.

Designing for rainwater capture and filtration is also essential in creating sustainable concrete flatwork projects. This design approach can help reduce the amount of runoff that goes into the stormwater system, which can cause pollution and erosion. Instead, captured rainwater can be used for irrigation or other purposes.

We can move towards a more sustainable construction industry and a healthier planet by using eco-friendly materials, choosing lower-carbon cement alternatives, and designing for rainwater capture and filtration.

The Path to Perfect Concrete Flatwork

Creating impeccable concrete flatwork is a fascinating combination of artistic creativity and scientific precision. It entails a deep understanding of the properties and characteristics of the materials involved, meticulous planning, and flawless execution. Maintaining the concrete surface is crucial to ensure its longevity, functionality, and aesthetic appeal. By following these guidelines and continuously exploring innovative solutions, you can attain concrete surfaces that are durable, practical, visually striking, and aesthetically pleasing.

Are you ready to transform your space with durable, stunning, meticulously crafted concrete flatwork? Whether you’re planning a new installation or seeking to enhance an existing surface, our team of experts in North Carolina, including Raleigh, Durham, Greenville, and the surrounding areas, guides you every step of the way. Get a free estimate now to explore innovative solutions and start creating concrete masterpieces that stand the test of time. Let’s build something amazing together!